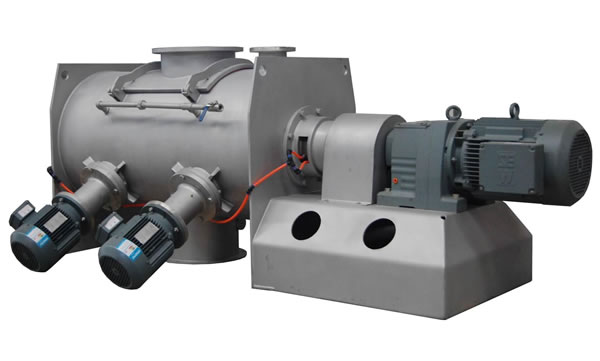

Overview

The model consists of a horizontal cylindrical shell, coulter, fly cutter, and driving mechanism four parts. Materials move convectively along the cylinder wall under the action of the coulter; when materials are sheared away by high-speed fly cutter if passing through the fly cutter, the materials are uniformly mixed in a relatively short time. It can meet the compound processes such as most of solid-liquid mixing and wet grain making and drying, and it is especially suitable for the mixing of viscous or gel materials.

Characteristics

1. Advantageous standard products are driven by adopting a belt pulley driving the cycloid reducer, and relative to the high torque of gear reducer, the elastic connection of belt transmission has the advantage of protection for the driving part at the time of overload.

2. The coulters uniformly distributed within the fly cutter drum during high-speed operation can also drive materials to circularly flow along the circular cylinder besides axial dispersion, and the fly cutter in the middle plays a role in auxiliary mixing and dispersed depolymerization of agglomerate materials.

3. Shape and speed of the fly cutter: a fly cutter group with multilayer blades is directly connected to the motor. The standard speed is commonly 1440 r/min, and there are a variety of shapes and speeds optional according to the different material characteristics.

4. An atomizing nozzle can be additionally arranged on the fly cutter, to add fluid for mixing, and since the crowding density of materials on this place under the cutting action of the fly cutter is small, the atomized liquid flows more easily into and mix with powder materials.

5. Feeding way: a feeding inlet is arranged in the upper part of the standard cylinder, fitted with a sealing cover, and fastened with lock; vacuum negative pressure loading can be achieved by means of non-standard customization.

6. Discharging way: this type of mixing machine can be made into a continuous mixing machine, and the residence time of material in the cylinder is controlled by adjusting the opening size of the discharging valve, in order to reach the purpose of controlling the mixing uniformity.

User’s customization

The following structural forms are customized according to user requirements.

1. According to material properties, appropriate configuration is increased, and a drying-mixing integrated system is formed. Drying is realized by means of conduction heating, with the obvious advantages of high efficiency and energy saving.

2. The cylinder can be designed to jacket form, and hot and cold medium is input to meet the user requirements for process temperature control.

3. It can be designed to operate under vacuum or pressure condition.

4. The upper cover, sealing device and discharging valve can be designed according to the user requirements by means of manual, pneumatic ways, etc.

Technical parameters

| Model |

Whole volume(m3) |

Loading coefficient |

Motor (kw) |

Overall dimensions(mm)

Maximum diameter x height |

Weight(kg) |

| LDH-0.1 |

0.1 |

0.4-0.6 |

3 |

1270×865×850 |

430 |

| LDH-0.3 |

0.3 |

0.4-0.6 |

4 |

2070×1050×1150 |

950 |

| LDH-0.5 |

0.5 |

0.4-0.6 |

5.5 |

2180×1200×1300 |

1100 |

| LDH-1 |

1 |

0.4-0.6 |

11 |

2830×1620×1550 |

1800 |

| LDH-2 |

2 |

0.4-0.6 |

18.5 |

3420×1810×1758 |

2520 |

| LDH-3 |

3 |

0.4-0.6 |

18.5 |

3420×2045×1983 |

3200 |

| LDH-4 |

4 |

0.4-0.6 |

22 |

4200×2140×2123 |

4836 |

| LDH-6 |

6 |

0.4-0.6 |

30 |

4680×2290×2448 |

8775 |

| LDH-8 |

8 |

0.4-0.6 |

45 |

5560×2390×2608 |

9360 |

| LDH-10 |

10 |

0.4-0.6 |

55 |

5140×2390×2850 |

9750 |

| LDH-12 |

12 |

0.4-0.6 |

55 |

5720×3110×2960 |

10660 |

| LDH-15 |

15 |

0.4-0.6 |

75 |

5920×3280×3140 |

11050 |